Introduction

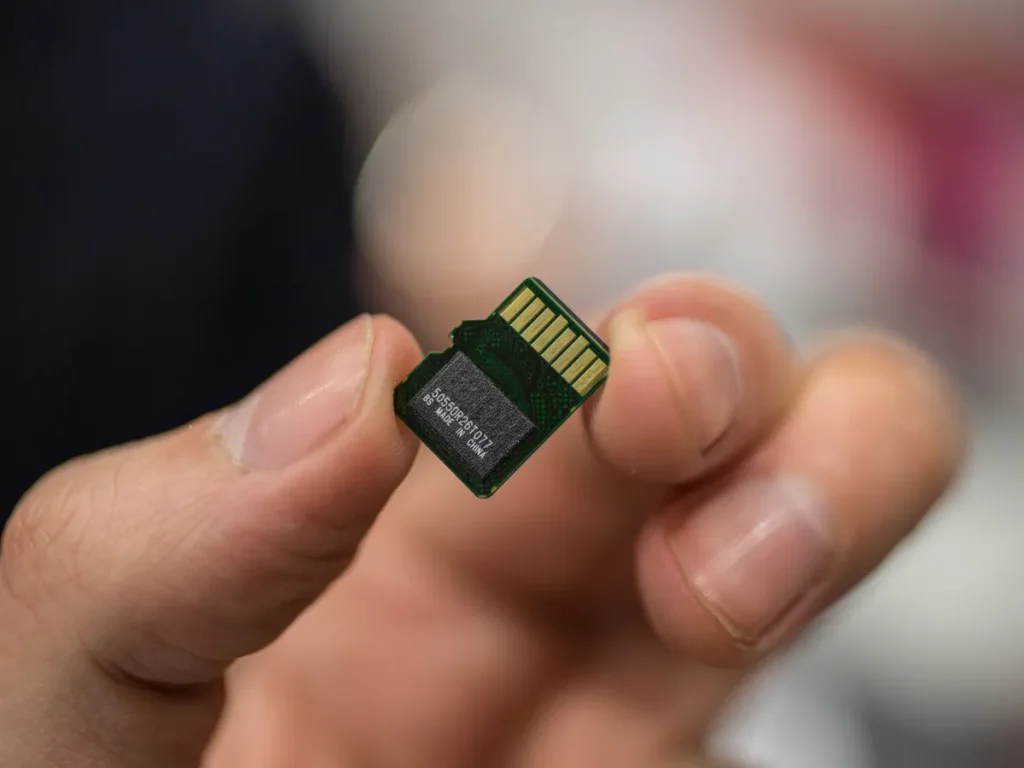

In the vast digital landscape, memory cards serve as the unsung architects of our data storage needs. The intricate processes of memory card testing and production form the bedrock of reliability, ensuring these compact devices become not just storage solutions but beacons of resilience. This article navigates through the meticulous steps, shedding light on the synthesis of precision and quality that manufacturers employ to engineer resilient memory cards.

Quality Assurance: Building the Foundation of Excellence

The journey of a memory card commences with an unwavering commitment to quality assurance, laying the foundation for manufacturing excellence. Every raw material and component undergoes meticulous scrutiny, setting the stage for a production process that prioritizes durability and reliability. This dedication ensures that each memory card emerging from the production line is not merely a storage medium but a paragon of quality craftsmanship.

Performance Testing: Unleashing Digital Prowess

The keywords, “memory card test and production,” reverberate through the performance testing phase, where the true digital prowess of memory cards is unveiled. Rigorous tests measure read and write speeds, data transfer rates, and cross-device compatibility. Manufacturers don’t just meet industry benchmarks; they aspire to unleash digital capabilities that go beyond expectations, elevating the user experience.

Endurance Trials: Forging Resilience in the Digital Forge

Endurance trials become the digital forge where memory cards are tempered for resilience. Stress tests simulate real-world scenarios, subjecting the cards to continuous data read and write cycles. The result is a memory card that emerges resilient, capable of withstanding the daily rigors of the digital realm and providing steadfast support to users in preserving their memories.

Precision Manufacturing: Crafting with Digital Artistry

Precision takes center stage in the manufacturing process, transforming it into a digital artistry. Leveraging cutting-edge technology and automated systems, manufacturers sculpt each memory card with meticulous precision. The production line operates with calibrated finesse, ensuring uniformity across various card types and capacities. Precision becomes the sculptor that elevates memory cards beyond mere functionality, turning them into digital masterpieces.

Automated Inspection and Compliance: Balancing Efficiency and Responsibility

The dance of automated inspection systems orchestrates a delicate balance between efficiency and responsibility. Real-time checks on physical attributes, electrical conductivity, and surface integrity create a symphony of quality control. Simultaneously, adherence to environmental and regulatory standards underscores the industry’s commitment to responsible production, ensuring that memory cards not only perform exceptionally but also adhere to ethical and ecological standards.

Conclusion: Engineering Digital Guardians

In conclusion, memory card test and production processes engineer not just storage devices but digital guardians of resilience. As technology continues to advance, the industry’s dedication to innovation and sustainability will shape memory cards into even more robust components. These unassuming devices, born from precision and tested for resilience, stand as formidable guardians, preserving our digital memories with unwavering strength in the ever-evolving digital landscape.